INDUSTRIAL FURNACES

Kumagawa produced have been contributing to create somethong new and valuable for society,

especially for infrastructures.

Please feel free to contact for the details.

VARIOUS HEAT TREATMENT FURNACES

|

Bogie type Heat treating furnace : oil or electricity. precise temperature distribution. 。 |

|

Roller Hearth type Tempering furnace : such as heating, tempering, hardening, and annealing. |

|

Pusher type Temperating furnace : and small products can be processed stably. This is trouble free and easy maintenance. hardening and annealing. |

|

Electrical Heating furnace : It is suitable for processing of preheating, distortion picking, etc. for the wide variety of products in smaller lots. The structure in which ceiling removal is possible. |

|

Continuous Carburizing furnace: suits as heat treatment by pusher or a walking beam type for continuous system for heating, annealing, sintering, and an object for calcination. |

|

Bell type Annealing Furnace : Furnace is shaped like a bell and the material to be |

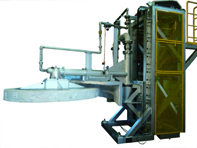

ALUMINIUM MELTING FURNACE

|

Alminium Melting furnace: It provides the tower charging device and holding chamber with an efficient burner arrangement. |

PRE-HEATING、SINTERING、ANNEALING & CLEANING DEVICE

|

The burner layout of burnout chamber for sintering furnace has been well considered for the smooth exhaustion. |

|

Gas-powered Pre-heating furnace for the ladle. It has been structured for the better pre-heating and ladle capacity. The fuel can be selectable for either gas or oil. We can design for the better energy-saving by the adoption of oxygen burner. |

|

Pre-process of sintering machine. Control is easy. |

|

Catenary type:It treated by the continuous annealing or tempering for the thin boards etc. |

|

Cleaning device by continuous type and batch type. You can expect the shorter operation by the showering and dipping procedures. |

Maintenance & Others

|

Industrial furnaces Incinerator Plant(Repair、Inspection、Cleanings) Guidance for measuring of exhaust gas |